Call: 08045814144

Double Wire Paper Machine

Double Wire Paper Machine Specification

- Grade

- Industrial Grade

- Type

- Double Wire Paper Machine

- Material

- Stainless Steel, Mild Steel

- Capacity

- 40-400 TPD (Tons per Day)

- Computerized

- Yes

- Control System

- PLC / DCS Automated Control

- Cutting Speed

- Up to 300 m/min

- Cutting Size

- 1575 mm 4200 mm (customizable)

- Cutting Thickness

- 0.1 mm 0.3 mm (paper web)

- Voltage

- 380V/440V, 50/60Hz, 3 Phase

- Power

- 200-1000 kW (model dependent)

- Weight (kg)

- 40000 180000 kg (model dependent)

- Dimension (L*W*H)

- Up to 100000*8000*7000 mm (customized)

- Color

- Industry Standard / Custom

- Headbox Type

- Hydraulic/Multi Layer

- Roller Diameter

- Up to 1500 mm

- Wire Section Type

- Double Wire Section for High Formation Quality

- Application

- Packaging Paper, Kraft Paper, Testliner, Duplex Board

- Speed Regulation

- Variable Speed (Inverter Controlled)

- Operating Pressure

- Up to 0.5 Mpa

- Maximum GSM Range

- 40 400 GSM

- Deckle Edge

- Up to 4200 mm

- Drive Method

- AC Variable Frequency Drive

- Design Standard

- International (ISO/CE)

- Press Section

- Hydraulic / Pneumatic Loading

- Drying Section

- Multiple Dryer Cylinders with Steam Heating

About Double Wire Paper Machine

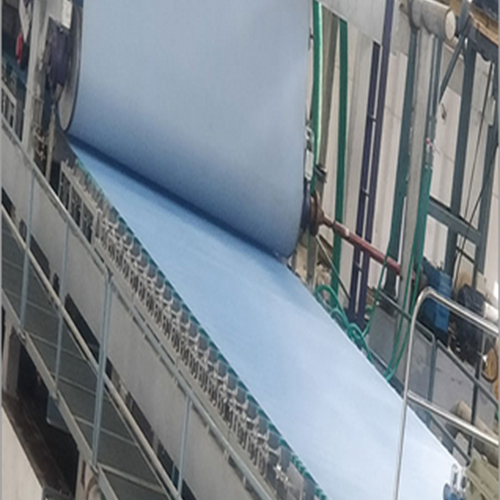

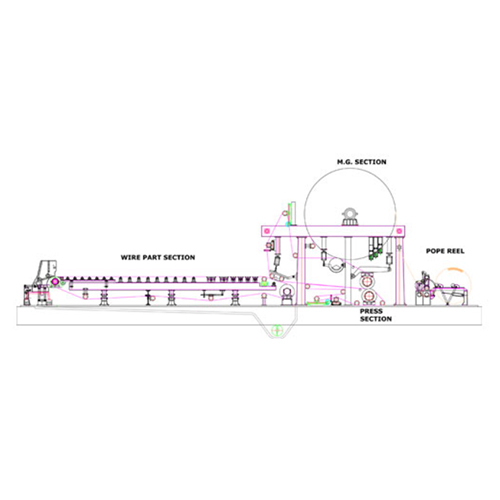

Discover the pivotal Double Wire Paper Machine, a sought-after solution designed for unrivaled paper formation and consistent performance. Its special double wire section ensures high formation quality, supporting a versatile GSM range of 40-400 for packaging paper, kraft paper, testliner, and duplex board. Select hydraulic/pneumatic loading and a hydraulically controlled headbox for superior precision. Powered by an AC variable frequency drive, this machine utilizes multiple dryer cylinders for optimal drying. Engineered to ISO/CE standards, it boasts fully computerized PLC/DCS controls, stainless steel construction, and exceptional adaptability-making it indispensable for India's top distributors, manufacturers, and suppliers.

Double Wire Paper Machine: Features and Versatility

This special Double Wire Paper Machine is engineered for superior formation quality, thanks to its double wire section and cutting-edge headbox design. Key features include variable speed (inverter control), PLC/DCS automation, and hydraulic or pneumatic press loading. Application extends across packaging paper, kraft, testliner, and duplex board production. With customizable dimensions, high-capacity operation, and stainless/mild steel materials, this pivotal machine delivers reliable performance and extra features such as multi-cylinder steam drying and industry-standard controls.

Export Markets and Supply Capacity: Global Reach and Value

We offer the Double Wire Paper Machine to sought-after export markets including Asia, Africa, Europe, and the Americas. Buyers benefit from competitive list prices and market value on bulk orders. Flexible delivery times and strong supply ability ensure your project deadlines are met seamlessly. Whether you are a distributor, trader, or manufacturer, our unrivaled capability supports reliable international distribution and prompt service, reinforcing the premium status of this industrial-grade equipment worldwide.

Double Wire Paper Machine: Features and Versatility

This special Double Wire Paper Machine is engineered for superior formation quality, thanks to its double wire section and cutting-edge headbox design. Key features include variable speed (inverter control), PLC/DCS automation, and hydraulic or pneumatic press loading. Application extends across packaging paper, kraft, testliner, and duplex board production. With customizable dimensions, high-capacity operation, and stainless/mild steel materials, this pivotal machine delivers reliable performance and extra features such as multi-cylinder steam drying and industry-standard controls.

Export Markets and Supply Capacity: Global Reach and Value

We offer the Double Wire Paper Machine to sought-after export markets including Asia, Africa, Europe, and the Americas. Buyers benefit from competitive list prices and market value on bulk orders. Flexible delivery times and strong supply ability ensure your project deadlines are met seamlessly. Whether you are a distributor, trader, or manufacturer, our unrivaled capability supports reliable international distribution and prompt service, reinforcing the premium status of this industrial-grade equipment worldwide.

FAQ's of Double Wire Paper Machine:

Q: How does the double wire section enhance paper formation quality?

A: The double wire section provides better fiber distribution and drainage, leading to superior paper formation and uniformity, especially important for high-quality packaging and board grades.Q: What types of paper can be produced with this machine?

A: This machine is suitable for producing packaging paper, kraft paper, testliner, and duplex board, accommodating a GSM range of 40-400.Q: When should you opt for hydraulic vs. pneumatic press loading?

A: Hydraulic loading is ideal for higher pressure and precision requirements, while pneumatic loading offers more flexibility and easier maintenance for various paper types.Q: Where is the Double Wire Paper Machine commonly used?

A: It is widely used in paper mills and manufacturing plants specializing in packaging, kraft, testliner, and duplex board production, both in India and internationally.Q: What extra features come with the PLC/DCS automated control system?

A: The PLC/DCS control system offers computerized monitoring, precise speed regulation, and streamlined operations, enhancing efficiency and reducing manual intervention.Q: How does the machine's AC variable frequency drive benefit users?

A: The AC variable frequency drive enables variable speed control for different grades and thicknesses, ensuring energy efficiency and operational flexibility.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Kraft Paper Machine Category

Single Wire Paper Machine

Minimum Order Quantity : 1 Unit

Color : Mid Green

Computerized : Yes

Control System : PLC Control

Grade : SemiAutomatic

Material : SS

Yankee Paper Machine

Minimum Order Quantity : 1 Number

Color : Blue / Green / Custom

Computerized : Yes

Control System : Other, PLC Controlled

Grade : Other, Industrial Grade

Material : Stainless Steel / Mild Steel

Trippele Wire Paper Machine

Color : Customized

Computerized : Yes

Control System : Other, PLC Based

Grade : Automatic

Material : Stainless Steel, Mild Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry