Call: 08045814144

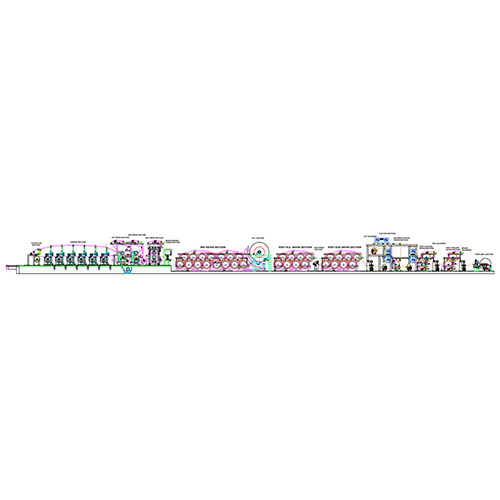

Coated Duplex Machine

Coated Duplex Machine Specification

- Connectivity Options

- Ethernet/Modbus/Remote Monitoring

- Machine Type

- Duplex Board Coating Machine

- Drive

- AC Servo/Variable Frequency Drive

- Model No

- CDM-8500

- Accuracy

- 0.2 mm

- Features

- High Efficiency, Consistent Coating, Energy Saving, Low Maintenance

- Power Rating

- 32 KW

- Motor Power

- 10-20 HP

- Control System

- PLC Control / HMI Touch Panel

- Cooling System

- Water Cooling / Air Cooling

- Frequency

- 50/60 Hz

- Operating Temperature

- 5C - 45C

- Voltage

- 380V/415V

- Frame Type

- Heavy Duty Welded Frame

- Lubricating System

- Automatic Grease/Oil Lubrication

- Noise Level

- <70 dB

- Production Capacity

- 3-9 Tons/Day

- Product Type

- Coated Duplex Machine

- Technology

- Automated / Semi-Automatic

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 32 kW

- Pressure

- Hydraulic/Adjustable (As per machine setup)

- Surface Treatment

- Coated/Polished

- Dimension (L*W*H)

- 8500mm x 2400mm x 2900mm (Customizable)

- Weight (kg)

- Approx. 13500 kg

- Color

- Silver / Sky Blue / Custom

- Usage & Applications

- Paper Coating, Duplex Board Manufacturing, Packaging Industries

- Operator Interface

- Color Touchscreen, Multilingual Supported

- Unwind/Rewind Type

- Hydraulic Shaftless

- Roller Material

- Hard Chrome Plated Steel

- Number of Coating Stations

- 2-3 (Customizable)

- Installation Service

- Available

- Coating Method

- Blade / Air Knife Coating

- Drying System

- Infrared + Hot Air

- Min. Web Width

- 600 mm

- Compressed Air Requirement

- 6-8 Bar

- Documentation

- Operation Manual, Maintenance Manual, Spare Part List

- Safety Features

- Emergency Stop, Safety Guard, Interlocked Panels

- Max. Web Width

- 2100 mm

About Coated Duplex Machine

Spotlight the champion of efficiency and durability with the CDM-8500 Coated Duplex Machine, featuring roller material in unprecedented hard chrome plated steel. Soaring beyond expectations, this machine supports advance purchase and complete customization-from coating stations (2-3) to dimensions and color. Benefit from a cutting-edge PLC/HMI control system, hydraulic shaftless unwind/rewind, and dual drying methods for consistent, energy-saving output. Safety is paramount, with emergency stop, interlocked panels, and smart safety guards. This automated marvel is designed for duplex board manufacturing and packaging industries, offering unparalleled productivity and reliability.

Primary Competitive Advantages and Commercial Applications

The Coated Duplex Machine stands out for its advanced safety features, high accuracy (0.2 mm), and exceptional efficiency-making it a preferred choice for discerning manufacturers. Its customizable design and heavy-duty construction provide commercial users, especially in the paper coating, duplex board, and packaging industries, with reliable, high-capacity solutions. Suitable for high-throughput environments, the machine's versatility ensures it exceeds stringent industry standards, empowering businesses to achieve unmatched quality and operational excellence.

Packaging, Payment Terms, and Delivery Timeline

Each Coated Duplex Machine is expertly packaged to guarantee safe shipping, with all crucial documentation-operation manuals, maintenance guides, and spare part lists-included. Shipped directly from the manufacturer or supplier, we estimate delivery within the committed lead time, ensuring timely installation service. Flexible payment terms are available, and we strive to offer the lowest price while maintaining premium quality. Our efficient logistics network streamlines freight and ensures the machine reaches your site in pristine condition.

Primary Competitive Advantages and Commercial Applications

The Coated Duplex Machine stands out for its advanced safety features, high accuracy (0.2 mm), and exceptional efficiency-making it a preferred choice for discerning manufacturers. Its customizable design and heavy-duty construction provide commercial users, especially in the paper coating, duplex board, and packaging industries, with reliable, high-capacity solutions. Suitable for high-throughput environments, the machine's versatility ensures it exceeds stringent industry standards, empowering businesses to achieve unmatched quality and operational excellence.

Packaging, Payment Terms, and Delivery Timeline

Each Coated Duplex Machine is expertly packaged to guarantee safe shipping, with all crucial documentation-operation manuals, maintenance guides, and spare part lists-included. Shipped directly from the manufacturer or supplier, we estimate delivery within the committed lead time, ensuring timely installation service. Flexible payment terms are available, and we strive to offer the lowest price while maintaining premium quality. Our efficient logistics network streamlines freight and ensures the machine reaches your site in pristine condition.

FAQ's of Coated Duplex Machine:

Q: How can the Coated Duplex Machine be customized to fit specific production requirements?

A: The Coated Duplex Machine offers customization in several aspects, including the number of coating stations (2-3), machine dimensions, color options, and additional features like connectivity and motor power. These options allow manufacturers to tailor the system to their exact application and space needs.Q: What commercial benefits does the Coated Duplex Machine provide for packaging industries?

A: This machine delivers consistent high-quality coating, fast throughput (up to 9 tons/day), and energy savings, enabling packaging industries to improve productivity, enhance product quality, and lower operational costs, thus securing a competitive edge in demanding markets.Q: When is the best time to place an advance purchase order for this machine?

A: Advance purchase is recommended once your production requirements are defined, especially if you require customization. Early orders allow for precise manufacturing, timely delivery, and scheduling of installation and training services.Q: Where is the Coated Duplex Machine typically installed and used?

A: These machines are primarily installed in paper mills, board manufacturing plants, and packaging facilities where duplex board coating and processing are essential to business operations.Q: What is the process for installing and commissioning the Coated Duplex Machine?

A: After shipping, skilled technicians provide on-site installation, commission the system, and offer comprehensive training. Documentation like operation and maintenance manuals ensures seamless setup and long-term performance.Q: How does the machine ensure operator safety during production?

A: The machine features emergency stop functions, safety guards, interlocked panels, and clear color touchscreen interfaces in multiple languages to ensure safe and intuitive operation for all personnel.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry